- Home

- Business Processes

- Industry Knowledge

- Aerospace Industry

- Automotive Industry

- Banking Domain

- BFSI Industry

- Consumer/ FMCG Industry

- Chemicals Industry

- Engineering & Construction

- Energy Industry

- Education Domain

- Finance Domain

- Hospitality Domain

- Healthcare Industry

- Insurance Domain

- Retail Industry

- Travel and Tourism Domain

- Telecom Industry

- Leadership Skills

- eLearning

- Home

- Functional

- Procure to Pay

- Define Accounts Payable

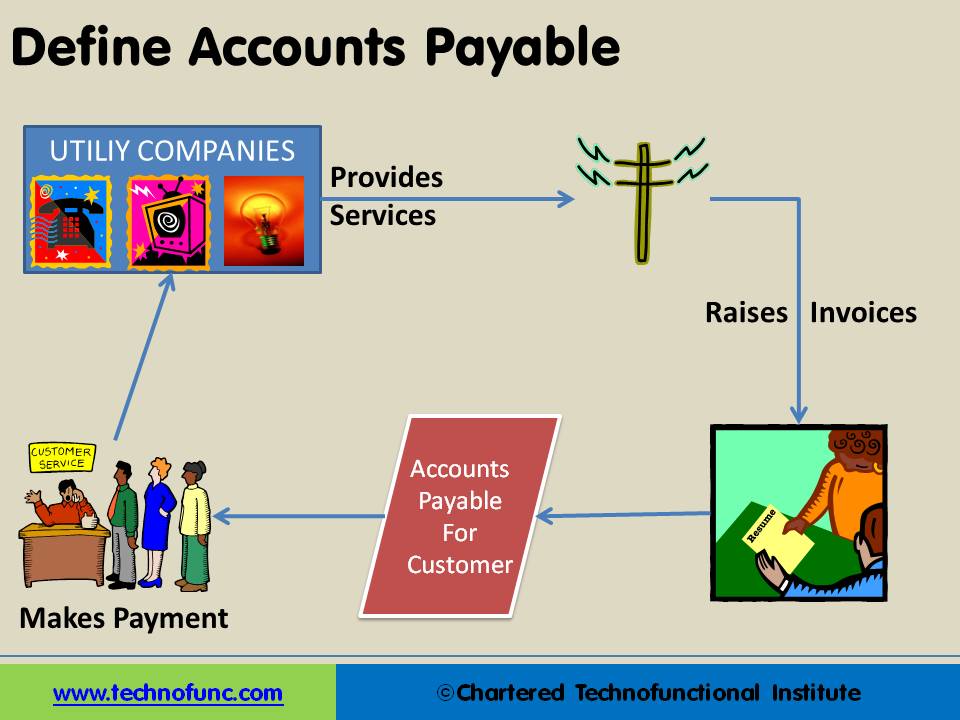

Define Accounts Payable

Payables are often categorized as “Trade Payables” & “Expense Payables”. “Trade Payables” are the monies due for the purchase of physical goods that are recorded in Inventory. “Expense Payables” are the monies due for the purchase of goods or services that are expensed.

How do we define Accounts Payables:

We all use utilities. For example we take various services from the phone company, the gas company and the cable company. They provide us the goods and services first and as the end of the agreed billing period they raise an invoice on the customer. In this case the Utility Company is our Creditor and they have provided us the service on credit. The amount payable to the utility company is the “Account Payable” for us, which needs to be paid in very short-term to the utility company (Supplier/Creditor) to enjoy continued services.

Similarly credit is extended in the normal course of business to the customers on purchase of goods and services and needs to be paid off within a given period of time in order to avoid default.

Payables are often categorized as “Trade Payables” & “Expense Payables”. “Trade Payables” are the monies due for the purchase of physical goods that are recorded in Inventory. “Expense Payables” are the monies due for the purchase of goods or services that are expensed. Common examples of Expense Payables are utilities like telephone and electricity.

Related Links

You May Also Like

-

Companies and businesses have huge transactions pertaining to their accounts payable process. They receive goods and services from various suppliers and they need to manage timely payments to these creditors to avoid default and adhere to the payment terms.

-

Warehouses can be places where piles of packed or loose products occupy space. If left disorganized, it will become very challenging to identify products for packing or picking. Hence, proper organization of warehouse is very important. Warehouse labeling systems eliminate this problem by making sure products are easily identified and managed during the warehousing and shipping process. Labeling is the most functional and cost-effective way to keep your warehouse organized and operating efficiently.

-

Inventory is money, and hence businesses need to perform physical inventory counts periodically to make sure that their inventory records are accurate. The traditional approach to conducting inventory counts is to shut down a facility during a slow time of year to count everything, one item at a time. This process is slow, expensive, and (unfortunately) not very accurate.

-

After products have been received and passed a quality inspection, they need to be stored so that you can find them when you need them. This process is called putaway. The spot where you store a particular product is called a location. One section of a warehouse might have small locations for light items; another area may have large locations on the floor for heavy items.

-

Accounts Payable Journal Entry

Although in the large organizations the Procure to Pay Accounting process starts when the purchase order for supply of goods is released to the supplier. To keep things simple in the beginning we will discuss the core accounting entries related to the Accounts Payables process.

-

One of the most important decisions when running a warehouse is its layout. Warehouse layout defines the physical arrangement of storage racks, loading and unloading areas, equipment and other facility areas in the warehouse. A good layout aligned with the business needs could have a significant effect on the efficiency.

-

Large companies have huge number of suppliers. To remain competitive they need to manage their procure to pay process very effectively. They create specialized division to handle these operations.

-

This article discusses the key documents that gets generated during the import/export process. These documents may apply to both invoice to cash as well as order to cash cycles. Also learn the major custom docments for India.

-

When a customer wants a product that has been stored in the warehouse, the same need to be picked off the shelf (or off the floor) and get it ready for shipping. Depending on how big is the warehouse, picking can take a while. (Many distribution centers cover more than 1 million square feet.). Hence, warehouse order picking methods are an important aspect within any warehouse.

-

One of the warehousing best practices that retailers like Walmart, Amazon, and Target have adopted is known as cross-docking. During this process the inbound products are unloaded at a distribution center and then sorted by destination, and eventually reloaded onto outbound trucks. In real parlance, the goods are not at all warehoused but just moved across the dock (hence the name).

Explore Our Free Training Articles or

Sign Up to Start With Our eLearning Courses

About Us

Learning

© 2023 TechnoFunc, All Rights Reserved