- Home

- Business Processes

- Industry Knowledge

- Aerospace Industry

- Automotive Industry

- Banking Domain

- BFSI Industry

- Consumer/ FMCG Industry

- Chemicals Industry

- Engineering & Construction

- Energy Industry

- Education Domain

- Finance Domain

- Hospitality Domain

- Healthcare Industry

- Insurance Domain

- Retail Industry

- Travel and Tourism Domain

- Telecom Industry

- Leadership Skills

- eLearning

- Home

- Functional

- Procure to Pay

- Accounts Payable Journal Entry

Accounts Payable Journal Entry

Although in the large organizations the Procure to Pay Accounting process starts when the purchase order for supply of goods is released to the supplier. To keep things simple in the beginning we will discuss the core accounting entries related to the Accounts Payables process.

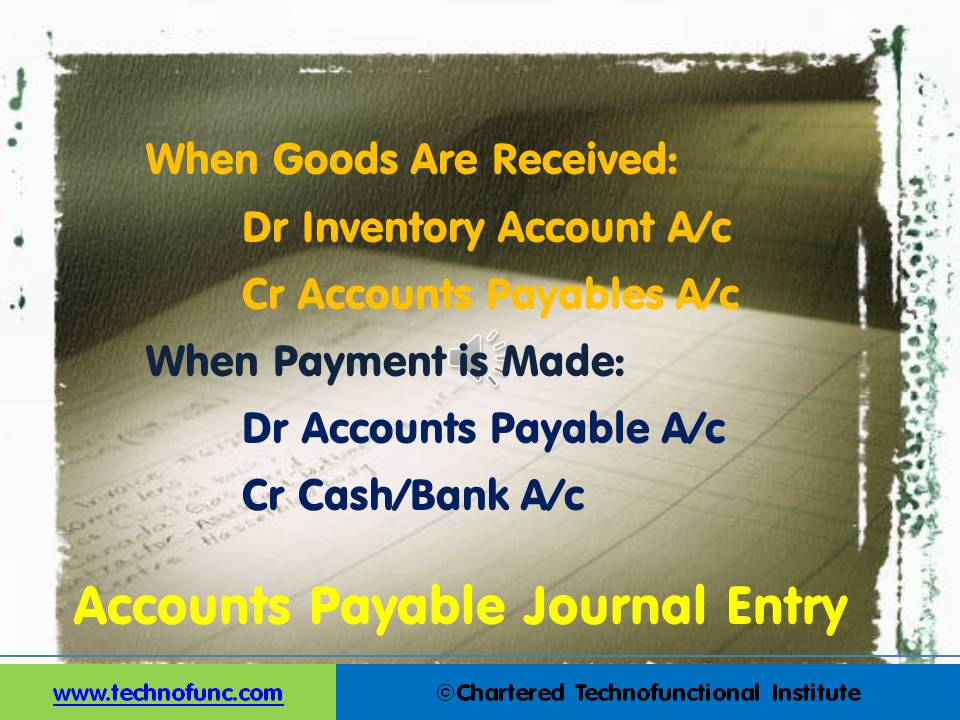

Accounts Payable Journal Entry

As discussed earlier “Accounts Payable” refers to the accounting entry that indicates a short term liability payable to the supplier of goods and services for the goods supplied or services rendered.

Although in the large organizations the Procure to Pay Accounting process starts when the purchase order for supply of goods is released to the supplier. To keep things simple in the beginning we will discuss the core accounting entries related to the Accounts Payables process.

Receipt of Goods:

You issue purchase order to the supplier and he supplies you with the goods. Once the ownership of the goods gets transferred from the supplier to us, we account for the goods as our inventory and based on the invoice received from the supplier need to create a liability for the payment due to him. At this stage the accounting entry is:

Debit Inventory Account

Credit Accounts Payable Account

Making Payment to the Supplier:

Once the payment for the invoice is released then funds gets released from the bank or cash and the amount due to the supplier gets knocked off. For this part the accounting entry is:

Debit Accounts Payable Account

Credit Cash/Bank Account

Related Links

You May Also Like

-

At a high level, the essential elements in a warehouse are an arrival bay, a storage area, a departure bay, a material handling system and an information management system. As part of the process for enabling a warehouse layout, you must define warehouse zone groups, and zones, location types, and locations.

-

Inventory is money, and hence businesses need to perform physical inventory counts periodically to make sure that their inventory records are accurate. The traditional approach to conducting inventory counts is to shut down a facility during a slow time of year to count everything, one item at a time. This process is slow, expensive, and (unfortunately) not very accurate.

-

This article discusses the documents that gets generated during the procure to pay process. Undestand why these documents are created, what is their business significance and how they are handled and generated using ERP or automated systems.

-

When a customer wants a product that has been stored in the warehouse, the same need to be picked off the shelf (or off the floor) and get it ready for shipping. Depending on how big is the warehouse, picking can take a while. (Many distribution centers cover more than 1 million square feet.). Hence, warehouse order picking methods are an important aspect within any warehouse.

-

Types of Inventory Count Processes

While dealing with lots of inventory in a warehouse, lots of things can go wrong. Shipments may not have the right number of units in them, or they could get damaged somewhere along the supply chain. Discrepancies in the stock may arise as part of every inventory control, and need to be corrected immediately after the inventory control procedure has been finished.

-

Large companies have huge number of suppliers. To remain competitive they need to manage their procure to pay process very effectively. They create specialized division to handle these operations.

-

We need a strong payables process so that it provides us with a high-productivity accounting solution to process vendor payments. An integrated payables process provides strong financial control so you can prevent duplicate payments, pay for only the goods and services you order and receive, and maximize supplier discounts. Understand the key features of an effective accounts payable system.

-

In the normal course of business, customers are likely to return orders from time to time due to various reasons and business should design processes the manage and accept such returns. A well designed returns management process can reduce costs and issues associated with returns or exchanges.

-

Business Case of Multiple Warehouses

Adding extra warehouses to business provides many benefits such as reducing shipping costs, increasing storage capacity, and having warehouses for specific purposes to simplify overall warehouse management. Multiple warehouses allow you to organize your inventory in a way that helps your business be more effective.

-

Before shipping, businesses need to make sure that the items will arrive in good condition. Packaging is a form of protection against environmental threats that the product will face from the time it leaves warehouse facility until the time it reached the customer. The packaging is intended to provide protection for the item as it is being handled in the warehouse or when the item is being shipped.

Explore Our Free Training Articles or

Sign Up to Start With Our eLearning Courses

About Us

Learning

© 2023 TechnoFunc, All Rights Reserved