- Home

- Business Processes

- Industry Knowledge

- Aerospace Industry

- Automotive Industry

- Banking Domain

- BFSI Industry

- Consumer/ FMCG Industry

- Chemicals Industry

- Engineering & Construction

- Energy Industry

- Education Domain

- Finance Domain

- Hospitality Domain

- Healthcare Industry

- Insurance Domain

- Retail Industry

- Travel and Tourism Domain

- Telecom Industry

- Leadership Skills

- eLearning

- Home

- Business Processes

- Procure to Pay

- Define Accounts Payable

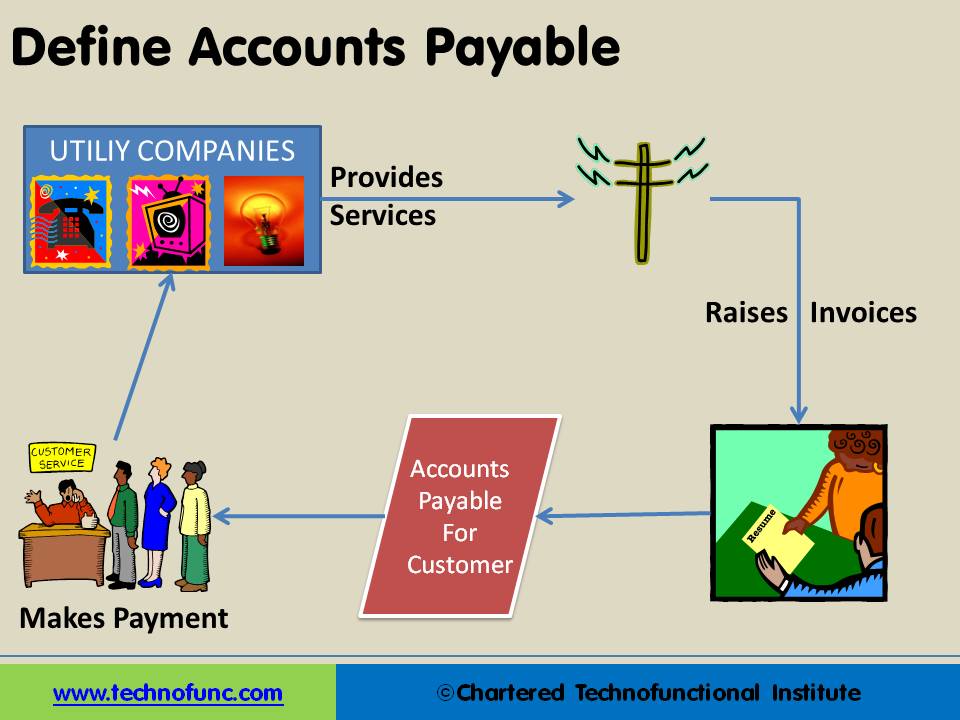

Define Accounts Payable

Payables are often categorized as “Trade Payables” & “Expense Payables”. “Trade Payables” are the monies due for the purchase of physical goods that are recorded in Inventory. “Expense Payables” are the monies due for the purchase of goods or services that are expensed.

How do we define Accounts Payables:

We all use utilities. For example we take various services from the phone company, the gas company and the cable company. They provide us the goods and services first and as the end of the agreed billing period they raise an invoice on the customer. In this case the Utility Company is our Creditor and they have provided us the service on credit. The amount payable to the utility company is the “Account Payable” for us, which needs to be paid in very short-term to the utility company (Supplier/Creditor) to enjoy continued services.

Similarly credit is extended in the normal course of business to the customers on purchase of goods and services and needs to be paid off within a given period of time in order to avoid default.

Payables are often categorized as “Trade Payables” & “Expense Payables”. “Trade Payables” are the monies due for the purchase of physical goods that are recorded in Inventory. “Expense Payables” are the monies due for the purchase of goods or services that are expensed. Common examples of Expense Payables are utilities like telephone and electricity.

Related Links

You May Also Like

-

Overview of Third-Party Logistics

Third-party logistics (abbreviated as 3PL, or TPL) is an organization's use of third-party businesses to outsource elements of its distribution, warehousing, and fulfillment services. A third-party logistics provider (3PL) is an asset-based or non-asset based company that manages one or more logistics processes or operations (typically, transportation or warehousing) for another company.

-

Large companies have huge number of suppliers. To remain competitive they need to manage their procure to pay process very effectively. They create specialized division to handle these operations.

-

Miscellaneous Warehouse Processes

At the end of each inventory control, the Contractor provides the Ordering Person with an inventory report which contains a list of all stock adjustments. The Ordering Person uses the report to create, by use of his/her own means, necessary value and accounting adjustments related to the stock. Let us look at some to the mislaneous warehouse processes not covered earlier.

-

What is the difference between Warehouse Management & Inventory Management?

The terms “inventory management” and “warehouse management” are sometimes mistakenly used interchangeably as they both deal with operations and products of industries. Despite their few similarities, there are many notable differences between warehouse and inventory management systems.

-

One of the warehousing best practices that retailers like Walmart, Amazon, and Target have adopted is known as cross-docking. During this process the inbound products are unloaded at a distribution center and then sorted by destination, and eventually reloaded onto outbound trucks. In real parlance, the goods are not at all warehoused but just moved across the dock (hence the name).

-

Understand the Accounts Payable process. Understand the AP cycle and the various tasks that need to be completed during AP transaction processing. Learn the key activities and setups that are done in any typical system during the AP processing.

-

Warehouses may seem like a simple, straightforward concept, but they actually include a variety of different types of warehouses that all have their own niche. The type of warehousing that’s right for you depends on your specific industry, location, and needs. From private warehousing, distribution centers, and climate-controlled warehouses, there’s an option to suit every business.

-

Overview of Warehouse Processes

The basic function of a warehouse is to store goods. This means that they receive deliveries from suppliers, do any necessary checking and sorting, store the materials until it is dispatched to customers. Traditionally warehouses were seen as places for the long-term storage of goods. Now organizations want to optimize their customer experience and try to move materials quickly through the supply chain, so the role of warehousing has changed.

-

Companies and businesses have huge transactions pertaining to their accounts payable process. They receive goods and services from various suppliers and they need to manage timely payments to these creditors to avoid default and adhere to the payment terms.

-

Types of Inventory Count Processes

While dealing with lots of inventory in a warehouse, lots of things can go wrong. Shipments may not have the right number of units in them, or they could get damaged somewhere along the supply chain. Discrepancies in the stock may arise as part of every inventory control, and need to be corrected immediately after the inventory control procedure has been finished.

Explore Our Free Training Articles or

Sign Up to Start With Our eLearning Courses

About Us

Learning

© 2023 TechnoFunc, All Rights Reserved